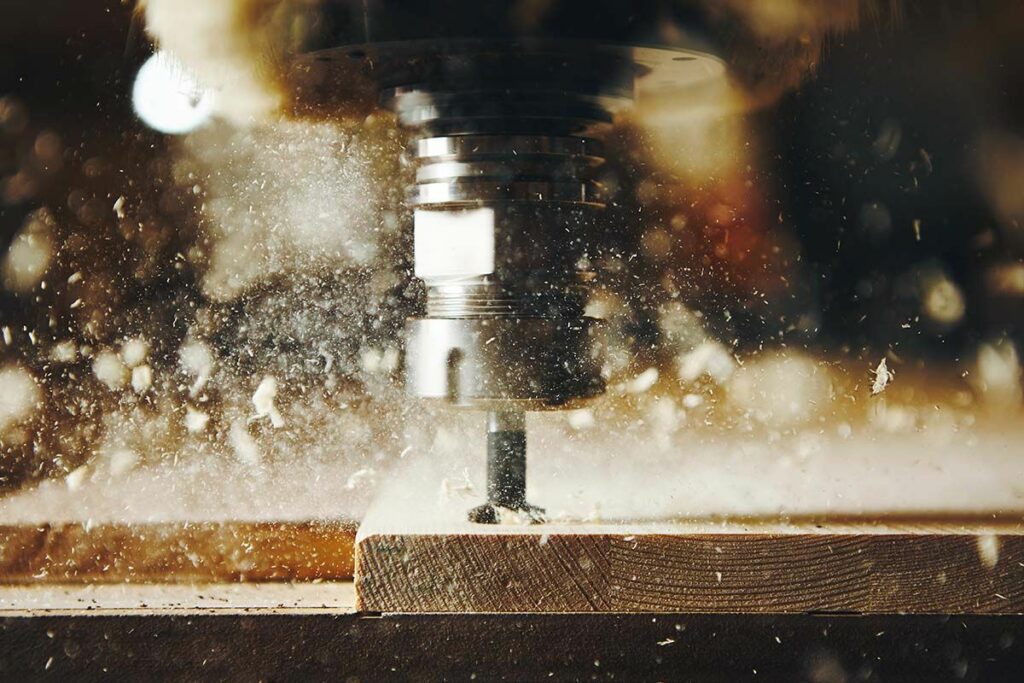

CNC (Computer Numerical Control) cutting is a production technique wherein industrial equipment and materials are controlled by pre-programmed software applications. There are various alternatives available to anyone wishing to have anything fabricated. They can get it laser cut, handcrafted, hammered, or manufactured, depending on their preferences.

A CNC cutting machine Hornetcs is an optimal alternative for anybody searching for extremely precise and high-quality materials. From crushers and drill bits to grinders and CNC processors, the procedure may be utilized to manage a wide range of complicated gear.

Three-dimensional cutting work can be performed with a single set of instructions with CNC machining.

Where can a CNC Cutting Service be Employed?

Just about every industry requires a custom CNC cutting machine. The following are some of the industries that demand CNC machining:

- Aerospace and Defense — goods made for this business include flight protective equipment and other aircraft-specific equipment.

- Signage – CNC machine shaping commercial sign fabrication. CNC machining with camera-vision finishing is evolutionizing the signage industry. Multiple axes of this machine can adjust to difficult angles and handle material that is difficult to cut, which makes it ideal for signs with a lot of plastic and metal parts.

More specifically, over tools like lathes, routers, grinders or mills by using specialized software that enables precise control of coordination, feed rate, location, speed and more.

- Architecture – in this case, you may require heavy work equipment that isn’t available anywhere else, especially if your construction is a one-of-a-kind design.

- Electrical – this includes the manufacturing of semiconductor components, enclosures, and cnc software.

Why Must Your Company use a CNC Cutting Service?

1) Parts with a high level of precision and reliability

CNC machining enables the creation of difficult-to-manufacture applications. The highly precise capability of CNC manufacturing guarantees that you receive exactly everything you need.

Furthermore, the production machine enables the traditional fabrication of common components until the last item you order.

2) Accuracy

A CNC machine is able to locate the registration points printed on the material with an accuracy of 1/1000th.

3) Machining Systems with Open/Closed Loops

An open-loop or closed-loop system decides awareness level during the CNC production process. Communication between the Control system and the motor is done individually with the latter.

A closed-loop system allows the operator to receive feedback, which also allows for error detection and correction. As a result, a closed-loop system can correct acceleration and location abnormalities.

4) Produce that is on time

CNC machining requires removing raw material units one by one until the desired shape is attained. The production equipment is controlled by a computer, ensuring that the speed is kept within a certain range.

Given that the machine is programmed to follow precise protocols, it is unlikely that an error will occur, resulting in the process being repeated. Additionally, a CNC cutting business has skilled CNC experts on staff.

UV direct flatbed printed materials can benefit from finishing equipment like CNC routers and lasers, which are equipped with camera vision technology, which reduces the workflow time.

4) Less effort is required

CNC machining necessitates the use of fewer people to complete industrial activities. One trained operator can operate numerous autonomous CNC machines, and one developer may put the necessary designs into them.

A manual device necessitates at least one trained operator per device, as well as a company manager. This gives you a competitive edge as you can use this effective cost-cutting in setting up better pricing or seasonal discounts.

5) Affordability

CNC machines are speedy, efficient, automated, and accurate, so they are an affordable alternative, especially when we talk about regular signage printers. Labor and time savings translate into lower customer costs.

6) Design Preservation

Whenever a concept has been fed into CNC machining technology and a flawless sample has been generated, the program may quickly retrieve the concept and run it again to obtain a product.

The file type ensures that irrespective of extraneous effects such as machine-operator modifications, the CNC manufacturing process produces a perfect match every time.

A bespoke CNC cutting machine is a vital industrial process because of its precision and accuracy. This cutting-edge technology helps work get done quicker with less labor. Certainly, with CNC cutting, your manufacturing production can supply thousands of items with quality and similarity.